Have you ever wondered how you can manage your manufacturing process within Odoo? Let us show you the basics of the manufacturing module in Odoo 13.

Below is a real-life example of a manufacturing process:

- Consider a Table, which will require one table body, four table legs and a few screws.

- First, at the wood cutting work station the wood will be molded into a table body and 4 table legs.

- Then at the assembly work station, the table Body and table legs will be joined using screws.

With Odoo’s manufacturing module, the above scenario can be done using the following method.

-

- First, you will have to go to Sales ? Products.

- We need a table body, table legs and screws to manufacture a table.

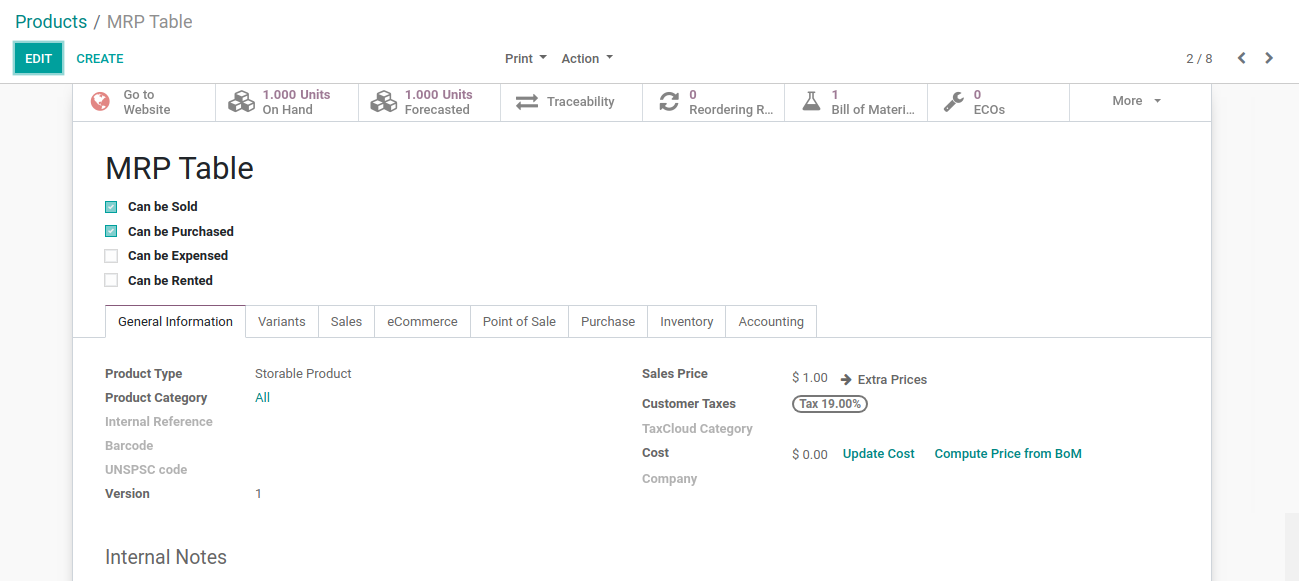

- Create a product for Table

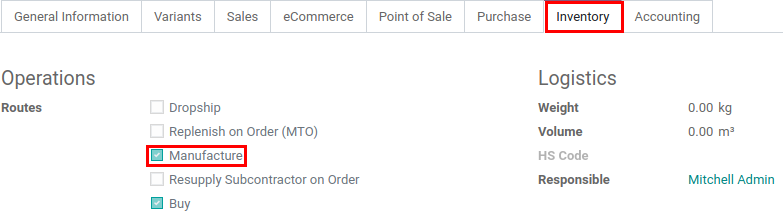

- When creating the table product, go to Inventory tab and check Manufacture in the routes.

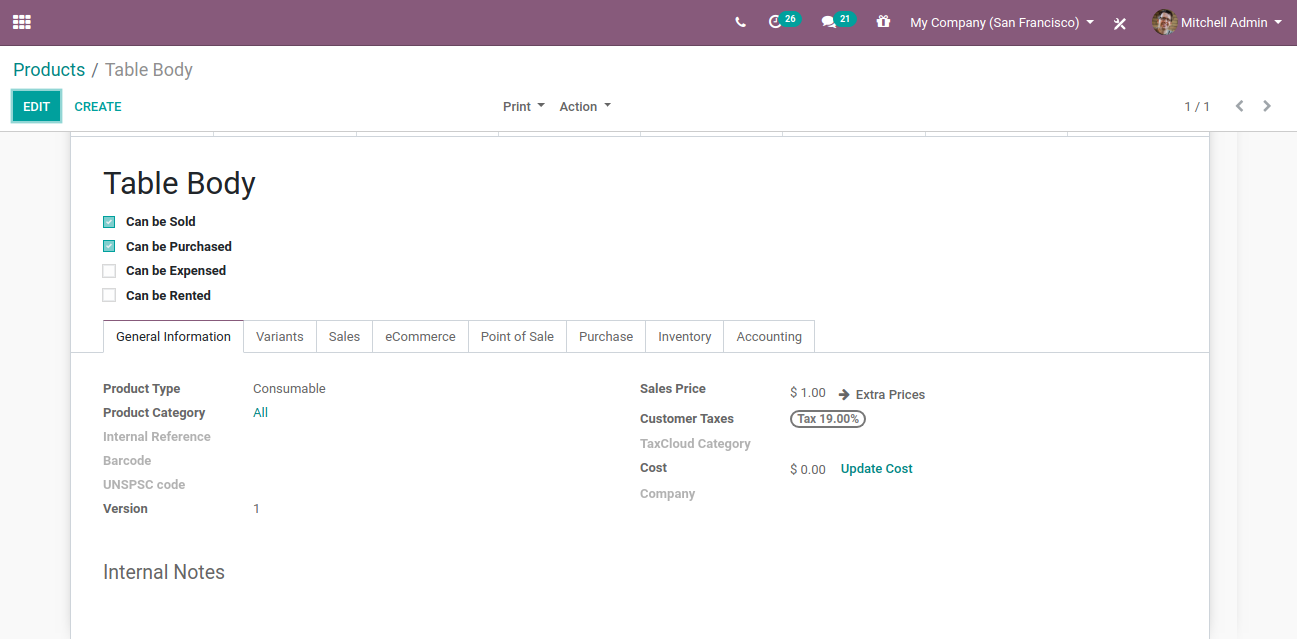

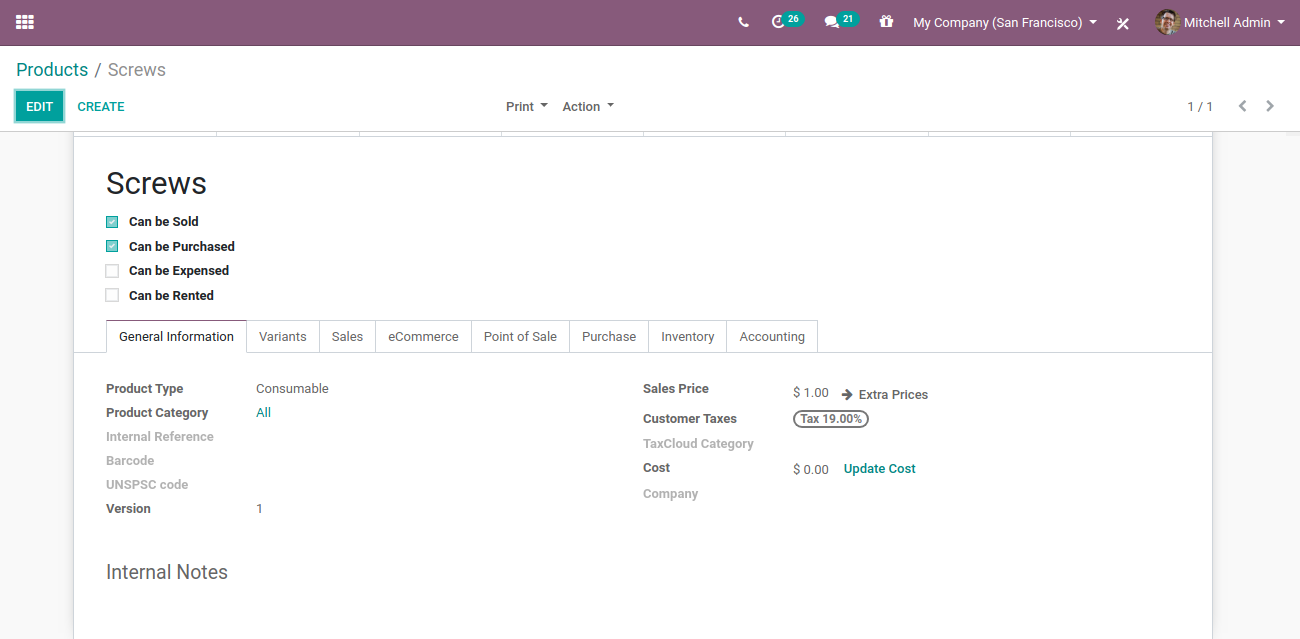

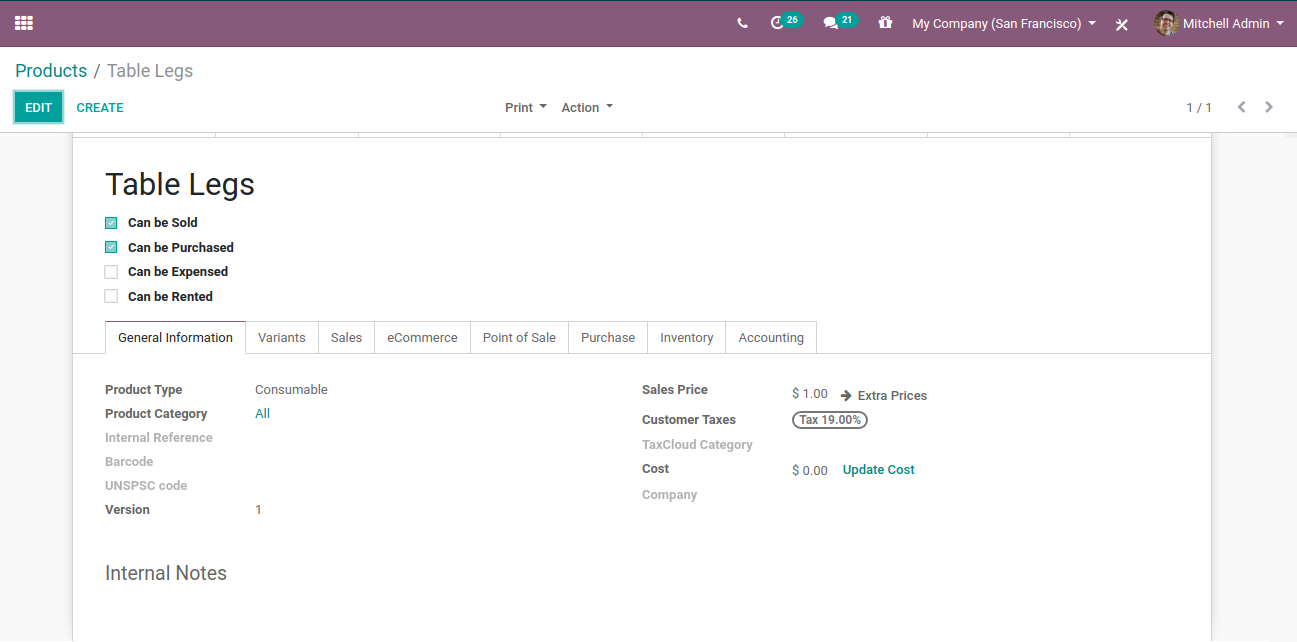

- Create Products for Table Body, Legs and Screws.

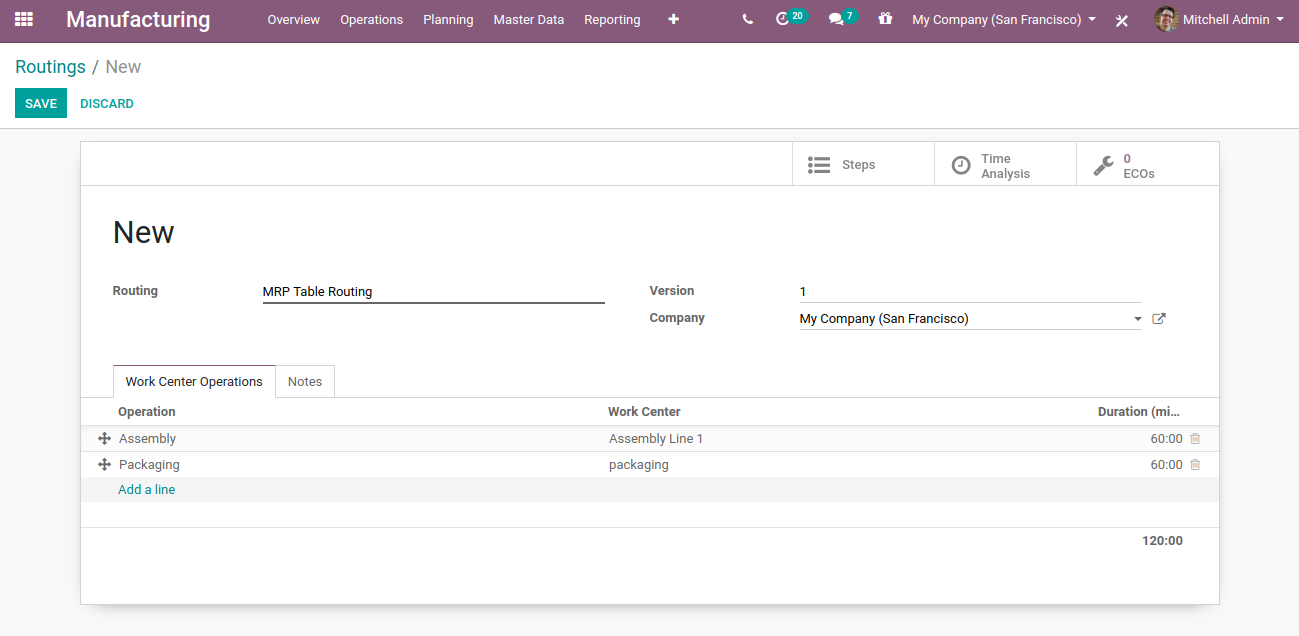

- Routing is the steps which the Manufacturing order will follow.

- When routing is selected in an Manufacturing order It creates a work order for every step defined in the routing.

- To create a routing, Go to Manufacturing ? Master Data ? Routing.

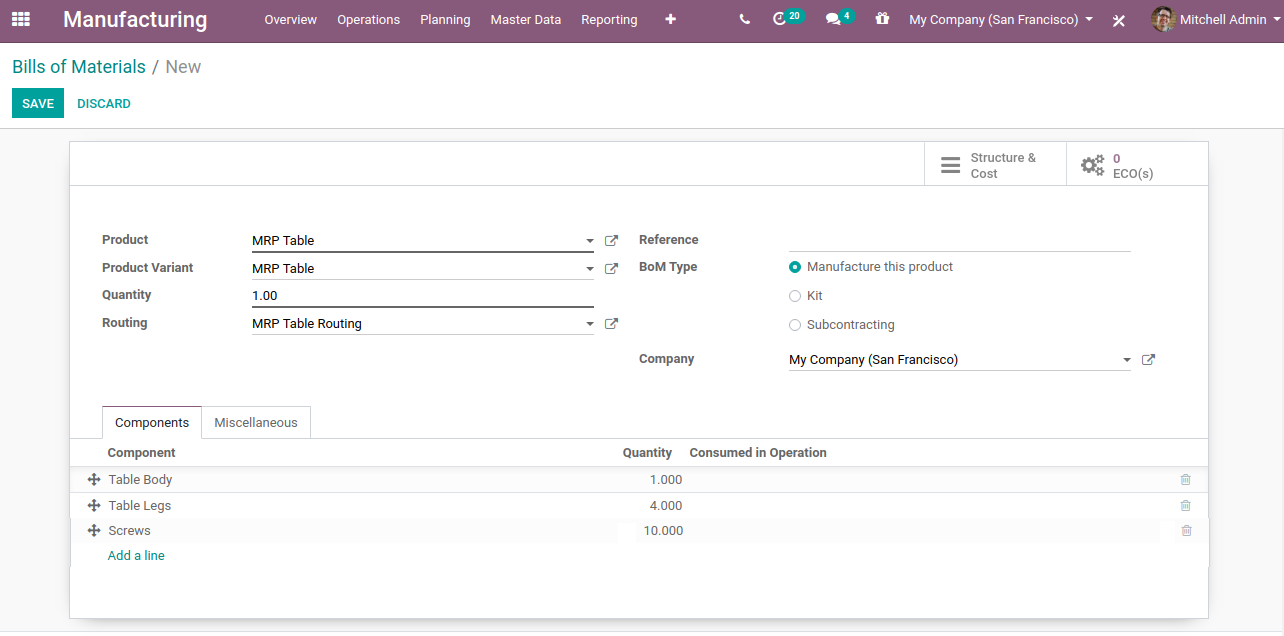

- Create BOM (Bill of Materials)

- Bill of Materials is a list of components/products which are required to manufacture the product.

- Go to Manufacturing ? Master Data ? Bill of Materials.

- You can create more than one BOM for the same product.

- You can select routing in BOM so It will be set by default when you choose this BOM in the Manufacturing Orders.

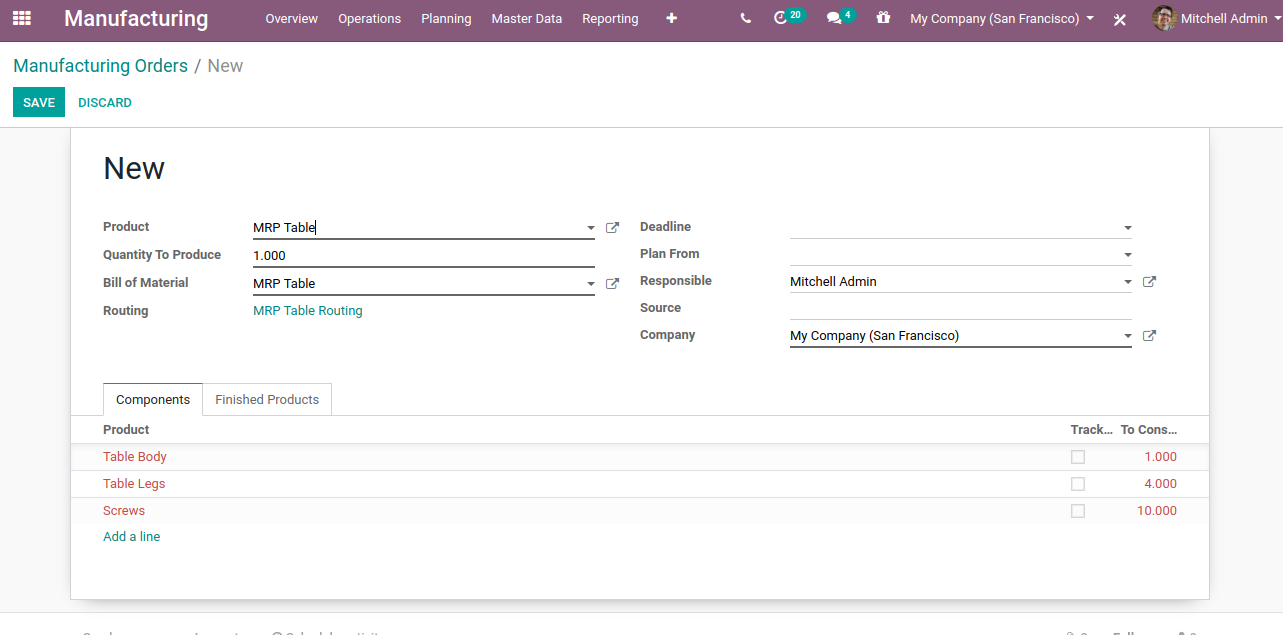

- Create Manufacturing Order

- Go to Manufacturing ? Operations ? Manufacturing Orders.

- Click On Create.

- Select Product.

- If you did not create a Bill of Materials for a product then that product will not be in the list of products in the product field.

- When you select a product then the BOM will be automatically selected. And If you have selected routing in the BOM then the Routing will also be automatically selected from BOM in the Manufacturing Order.

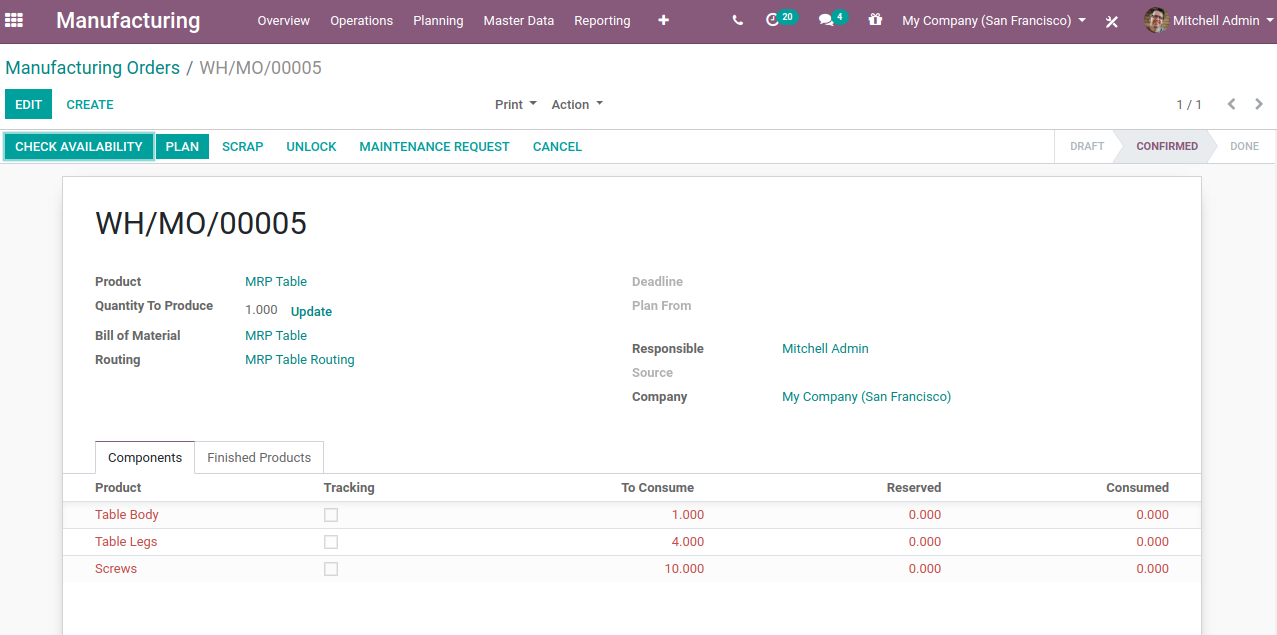

- Open MRP order and click on MARK AS TODO.

- When you click on MARK AS TODO then the state of the Manufacturing Order will change from draft to confirmed.

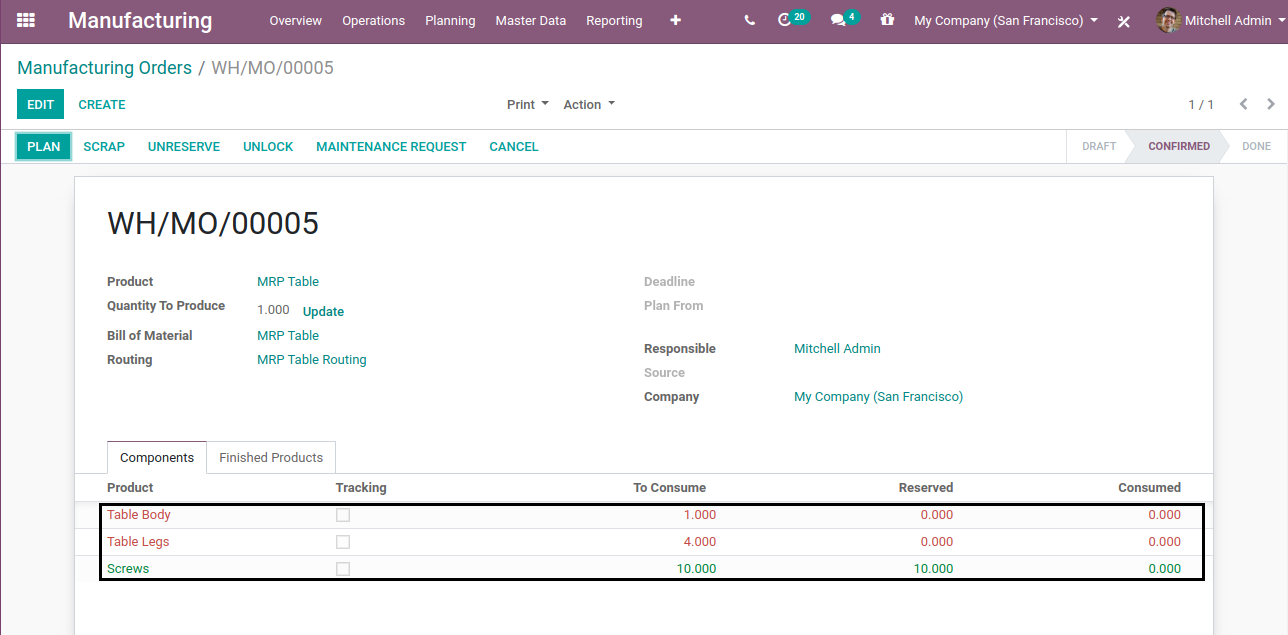

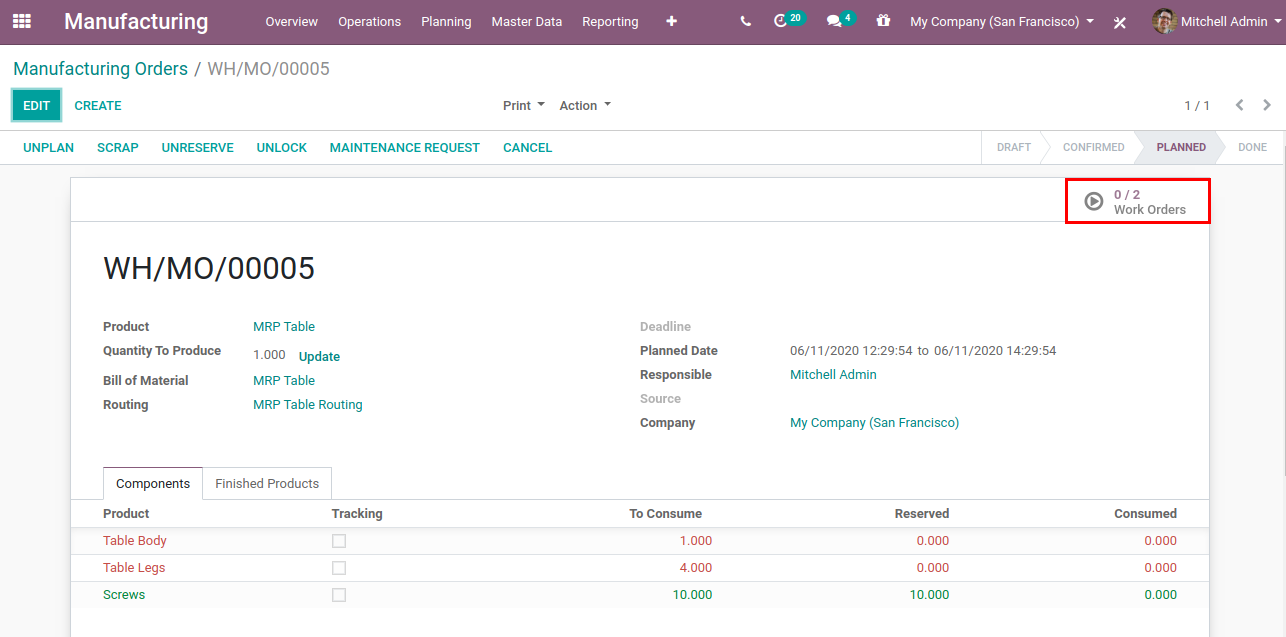

- Click on CHECK AVAILABILITY.

- When you click on CHECK AVAILABILITY It will reserve the components/products which are required to manufacture the table.

- If the product type is consumable than regardless of the current stock this will be reserved and will be shown as green.

- If the product type is storable then If the required quantity is available, only then the quantity will be reserved.

- Click on PLAN.

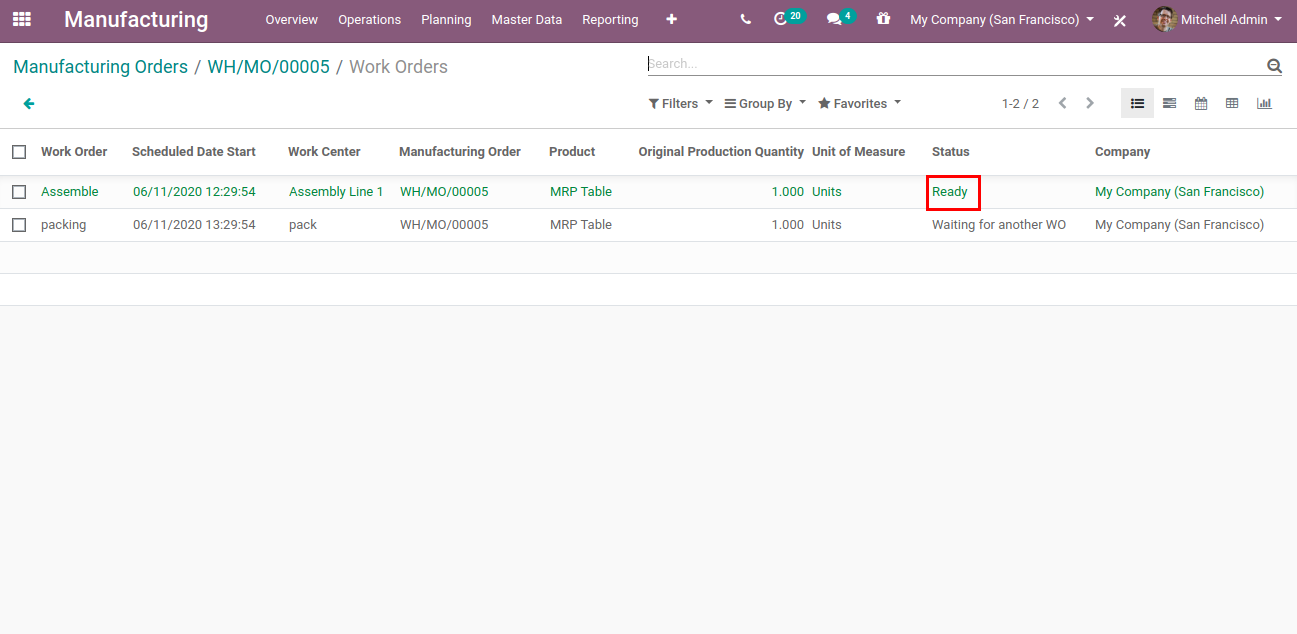

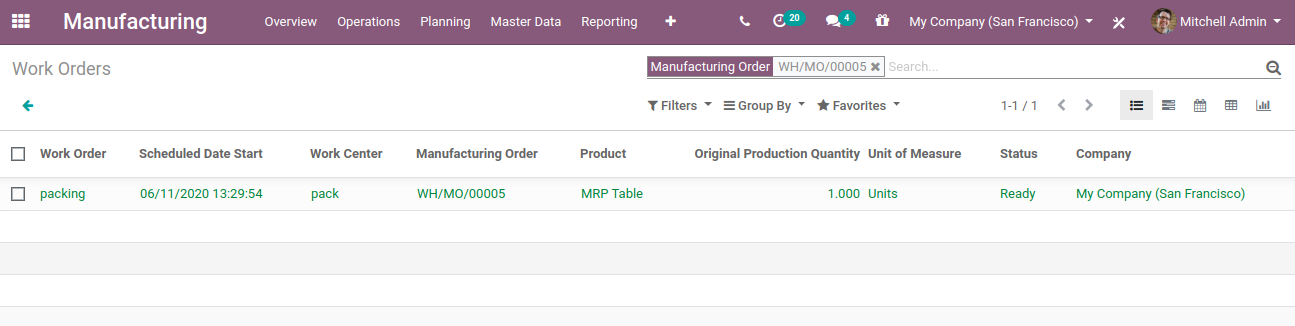

- Click on Work Orders.

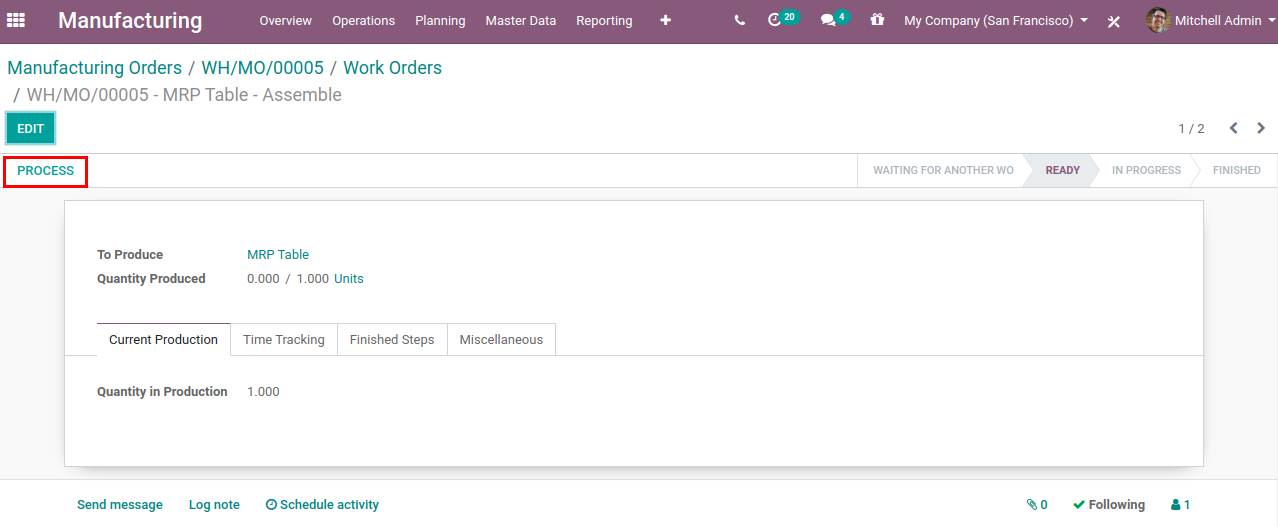

- Click on the work order which is in ready state.

- Click Process.

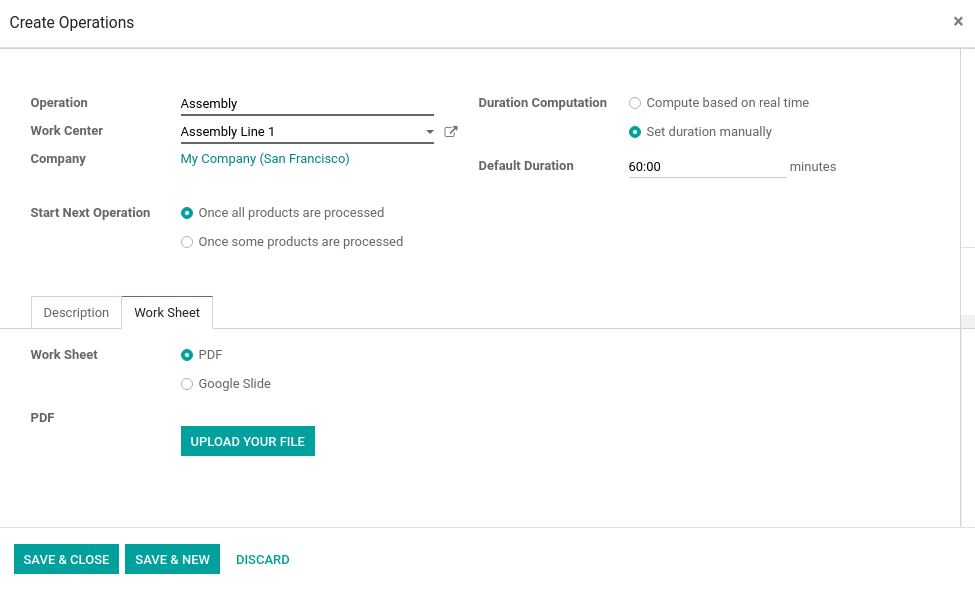

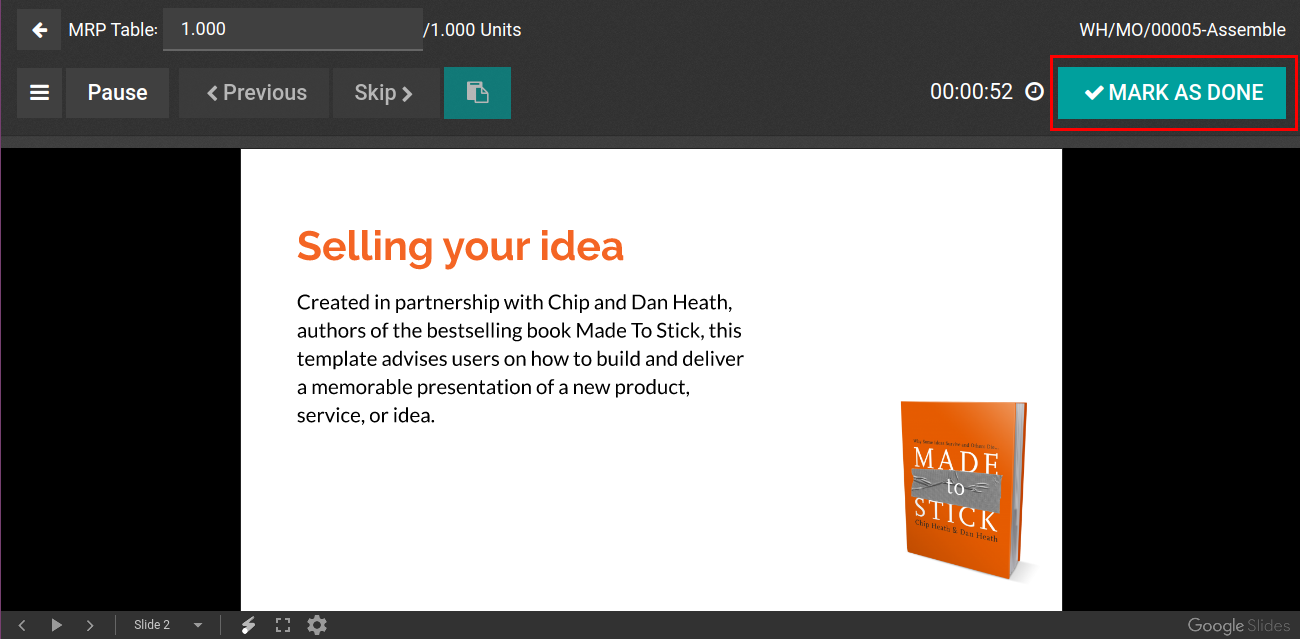

- If you added a pdf or google slide link the routing operation then It will be shown when you click on Process

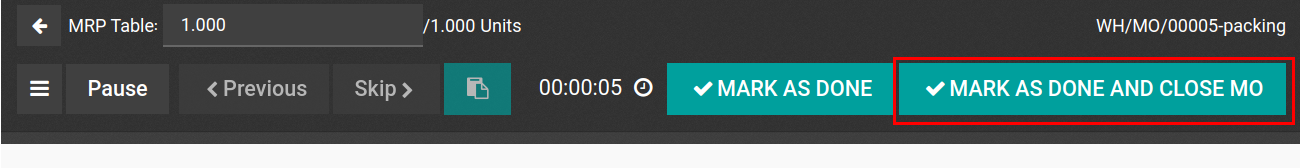

- Click on Mark as Done.

- This will show the remaining work orders for this MO(Manufacturing Order) and also which work order should be processed next.

- Repeat the same process for work order until you see Mark as Done and Close MO button.

- When Pressed the MARK AS DONE AND CLOSE MO button, the MO will be processed and the product will be increased with the quantity entered in the MO to your inventory.

This is the Basics of Manufacturing in Odoo 13.

Did you find this demo useful? Let us know what you think about the same in the comments section and we would be happy to hear from you. Also check out the Odoo development services we provide.

For professional paid support, you may contact us at [email protected] .