Supply chain management has become a critical factor for business growth in different sizes of organizations across various industries. Besides, Enterprise resource planning (ERP) has benefited businesses to organize their complex supply chain.

However, companies have been facing critical challenges in supply chain resilience. Causes might be a lack of supplies, unexpected events, disruptions in the market, varying costs, unpredictable demands, human labor, and many more.

Here, we have highlighted key challenges in legacy supply chains and how to leverage the tech benefits of ERP system implementation for driving business growth. Well, do you think implementing an ERP system in the supply chain can be beneficial for businesses? Let’s dive in and find out.

Challenges in Supply Chain Management

- Supplier Challenges: Raw material shortage and varying costs of supply

Inaccurate predictions, unavailability, varying costs, global shortage, inflation, improper planning, warehouse management errors, and poorly managed data are key challenges for suppliers in recent practices.

- Logistic Challenges: Reliable carrier, transportation costs, delays

Logistic challenges that make a supply chain vulnerable are escalating freight costs, improper tracking, reliability on logistic services providers, shattered communication, driver shortage, capacity, and labor shortage.

- Manufacturing Challenges: Quality, production, inventory management, and manufacturing cost, meeting deadlines

Manufacturing/production/assembly is no exception when discussing challenges. Poor quality of products, availability, demand forecasting, inventory management, material wastage, quality control, sustainable development, deadline, emerging technology, and lack of skilled labor are key challenges for manufacturing and/or assembly organizations in the supply chain.

- Distribution Challenges: Broken links, delivery delays, improper information, trade restrictions

Low margins, higher competition, service charges, taxes, legal actions, improper labeling, increasing transportation costs, trade restrictions, outsourcing consistency, and reliability of deliveries are some challenges for the distribution network in a supply chain.

- Retail Challenges: Keeping up industry demands, consistent sourcing, lack of technology, storage, On-time pickup, and delivery performance

When it comes to retail, changing consumer demands, storage, on-time deliveries, precise locations of an end-user, and relationship management are some of the key concerns.

- Customer Challenges: Dissatisfied customers, unexpected demands, returns & refunds, quality of products

End-users or customers affect supply chains the most. Increased/decreased demands, non-consumer-centric goods, improper purchase channels, unidentified locations, and instant-changing markets are some of the key challenges that customers create, which affect a supply chain.

The COVID-19 pandemic negatively affected around one-third of global companies. Challenges in supply chains can cause disruptions. Such disruptions cause excessive damage to businesses. There is an emergence of changes in supply chain approaches.

ERP FOR DIGITAL TRANSFORMATION OF SUPPLY CHAIN

Before we proceed to understand how to implement ERP systems in your business model, let’s highlight some of the crucial benefits and key features of ERP in a supply chain.

What is ERP?

Enterprise Resource Planning (abbreviated as ERP) is a software and/or platform that integrates and manages business-critical functions of finance, accounting, supply, inventory, manufacturing, human resources, and much more, with customized tools and modules.

Benefits of ERP System Implementation across various stages in Supply Chain Management

Restructuring the supply chain using advanced technology such as data analytics, and IoT to automate the flow of operations from supplier to manufacturer to distributor to end-user is known as digital supply chain management.

Here, we have highlighted how the implementation of ERP software can change the supply chain efficiency at different levels of a business.

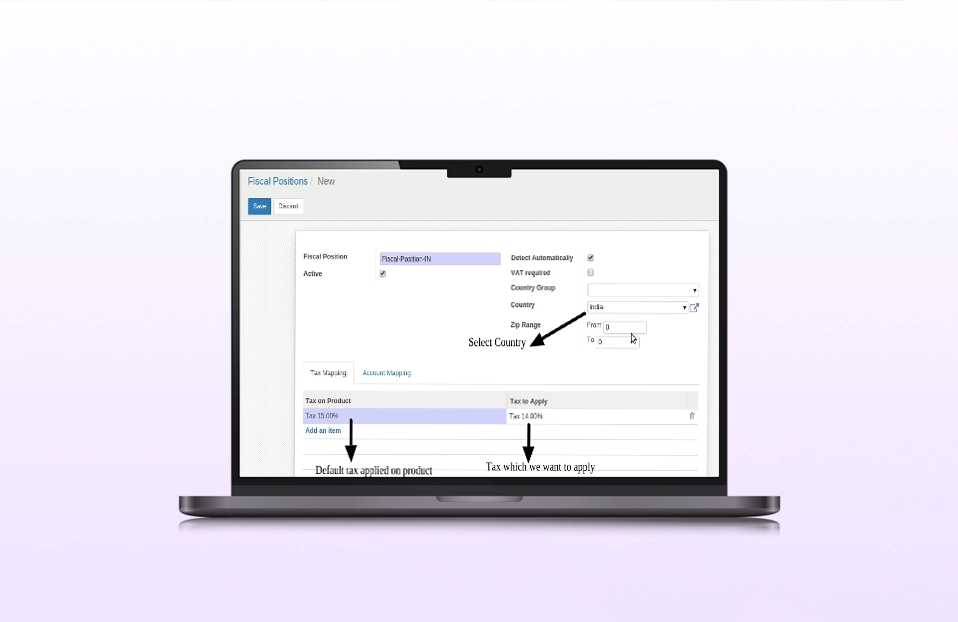

With an ERP platform, organizations can purchase the best possible raw materials from suppliers after comparing costs, availability, expected delivery, reliability of suppliers, and a backup plan. This can be done using sourcing technology and process optimization between organizations offered by ERP systems.

- ERP in Inventory Management

How easy would it be if you could get reports of orders, available material, forecasted items, shortage of goods, and requirements of merchandise at your fingertips?

An ERP platform allows businesses to balance supply with demand, optimize quality inventory, quality checks, material requirement planning (MRP), bill of materials (BOM), and control supply and purchase. These can all be done with simple tools such as order management, barcodes, warehouse management, inventory tracking, and reports.

- ERP in Manufacturing Operations

With manufacturing operations management tools, an ERP can outline the complete work-in-progress outline of your business in the palm of your hand. ERP software enables businesses to supervise buying, merchandising, inventory management, warehousing, transportation, real-time planning, risk management, and compliance, everything at once.

- ERP in Distributions & Logistics

Businesses can plan, control, and execute the movement of their products in ERP with tools and modules for logistic Management, warehouse locations, preferred routes, reordering, geolocation, automated deliveries, and vehicle movements.

Business owners can also oversee sales order processing, shipping orders, dispatch, mobility, and functions of packaging and labeling. Moreover, with predictive shipping, forecasting demands, and advanced delivery tools, businesses can reduce delivery time.

It gets quick and easy to compare the costs of supply with pricing engines. An ERP system also allows the evaluation of trends in the market. With tools for trade promotions, buying performance, micro-segmentation, and analysis, businesses can advertise, upsell or cross-sell relevant products specialized for each individual.

Customers are, of course, the most influencing factor in the supply chain. With an ERP platform, it is possible to deliver a customized and specialized experience to each individual.

End-to-end transparency and updating a user for the expected manufacturing and delivery can build customer engagement that is profitable for businesses. With a digital platform, we can also offer services like customer complaints, and return and refund policies.

A digitized supply chain with an ERP platform enables organizations to take complete control over their finances from accounts receivable, payable, ledger, balance sheets, and financial statements. It will ensure on-time collection, pay suppliers on time, and oversee the complete financials of an organization at your fingertips.

ERP Modules in Supply Chain Management

- Procurement

- Manufacturing

- Sales Management

- roject Portfolio Management

- Order Management

- CRM- Customer Relationship Management

- Logistic Management

- Value Chain Execution

- Finance Modules

Conclusion

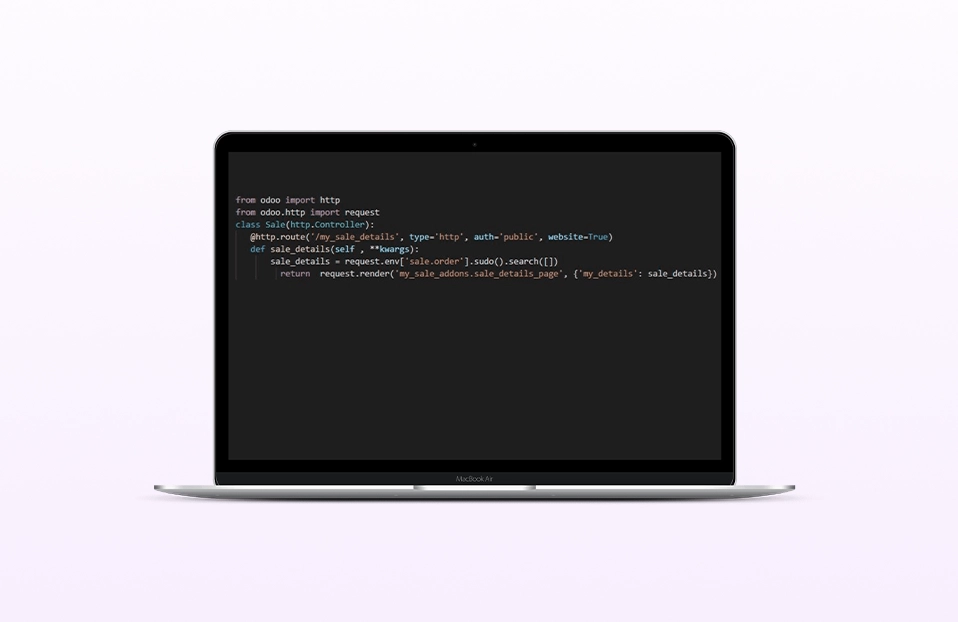

After looking at the current challenges in the supply chain, we can conclude that there is an emergence of changes in the same. With Odoo ERP system implementation , one of the best ERP service providers, it is possible for businesses to improve efficiency in the Supply Chains.

Implementing an ERP system can reduce production costs, fulfill customer demands, manage finance, build customer relationships, and offer many other benefits.

If you have been planning to implement ERP in the supply chain management for your business, you can connect to us. We are an ERP implementation consultant, and our skilled developers will assist you with planning for implementing an ERP system to execute it thoroughly.