Incorporating Digital Transformation through Odoo ERP Services for Leading Canadian Linen Manufacturer - Surekha Technologies

Struggling with your project?

DXP | ERP | E-Commerce | AI-ML | DevOps | Bespoke Solutions

Trusted By

Incorporating Digital Transformation through Odoo ERP Services for Leading Canadian Linen Manufacturer

Our client, a leading Canadian distributor of commercial linens and industry apparel, faced challenges with managing multiple applications, operational delays, and inconsistent inventory management.

To address these issues, we implemented a comprehensive Odoo ERP system integrated with their eCommerce platform. Our approach involved consulting to map out their needs, designing an intuitive UI/UX, developing a tailored ERP solution, and performing QA testing to ensure seamless and improved operational efficiency. This integration aimed to streamline their processes and eliminate the need for different systems.

- Number of Employees : 120+

Project Brief

Our client is Canada's leading distributor of commercial linens, facility supplies, healthcare, and industry apparel since its inception in 1995. They have built a reputation for reliability and trust by partnering directly with international manufacturers and industry-leading suppliers. With an extensive product selection and satisfactory customer service through their eCommerce platform, they have become one of the fastest-growing businesses in Canada.

Business Needs & Challenges

The client has to use multiple applications/software to manage different tasks, such as manufacturing, accounting, inventory management, procurement, quality checks, and sales.

The inefficiencies in coordination due to distributed works, which caused delays in various operational processes.

Ineffective progress status tracking of projects due to broken links in workflows.

Errors caused due to manual entries of purchase, sales, and inventory data.

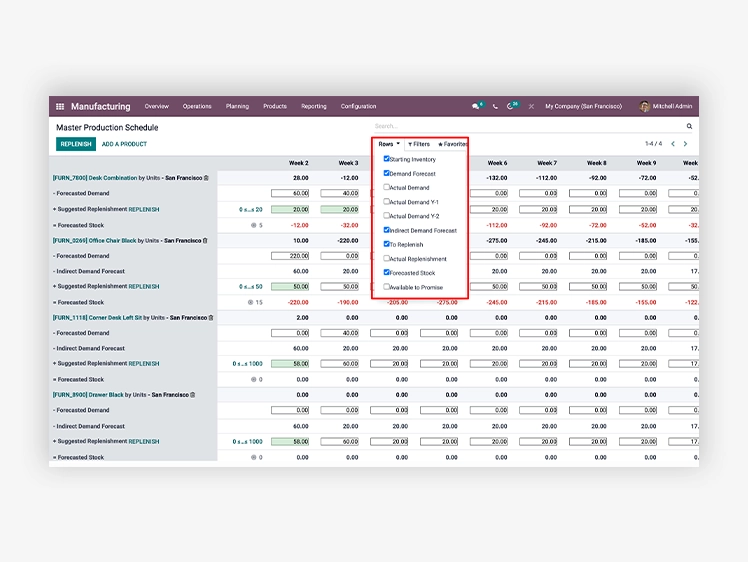

Inventory issues arising from manual entries and improper planning, leading to inconsistencies and unreliability.

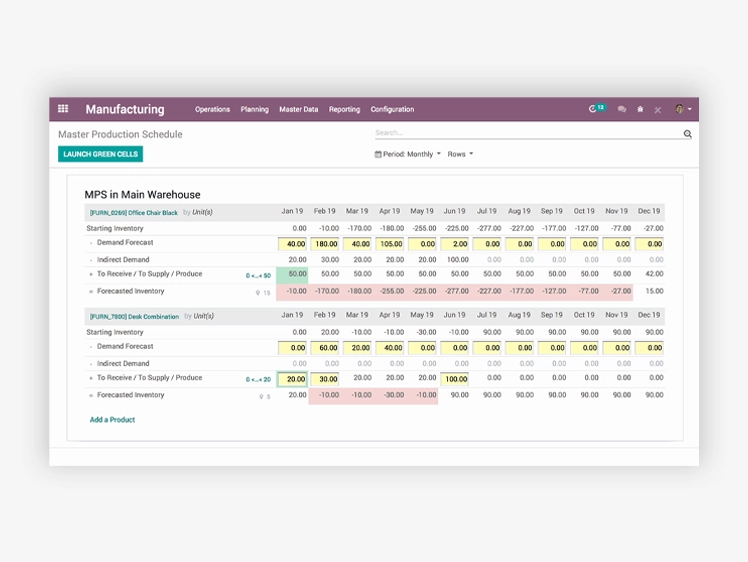

Challenges in manufacturing operations due to inadequate planning considering the needs of MRP and PLM

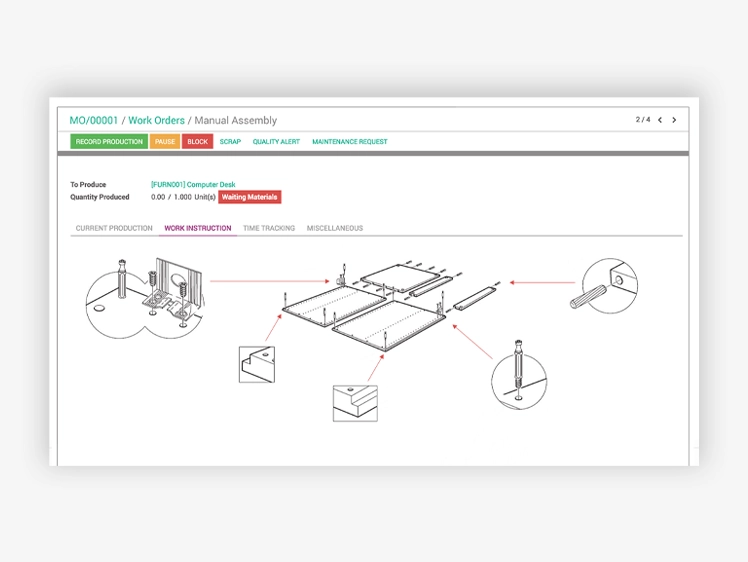

Complexities in managing manufacturing processes due to the custom business model.

Difficulties in creating sales quotations without proper references or historical data.

Difficulty in maintaining customer information and communication records without an ERP system.

Technology Stack & Tools

Implementation Overview

Business impacts

By integrating all multiple tasks considering various departments into a centralized ERP system, the company streamlined their operations, which enhanced overall productivity.

By implementing centralized collaboration tools and workflow automation, the team smoothen coordination and minimized operational delays.

With automated data integration and validation, they reduced manual errors in purchase, sales, and inventory data. Also, the advanced inventory planning module ensured the right stock levels at the right time, which reduced the risk of stockouts and overstocking.

Integrating MRP and PLM functionalities enabled the client to plan effectively in manufacturing operations.

The dynamic quotation generator simplified and accelerated the quotation creation process utilizing historical data and references, which lead to quicker response times and accurate sales operations.

The CRM system integration into the ERP delivered a holistic view of customer data and communication records, which enabled the client to offe personalized customer experience.

By streamlining operations, improving efficiency, and leveraging data-driven insights, the linen manufacturing company improved ROI on technology spending.

Overall, the implementation of these solutions paved the way for the company's digital transformation journey. By embracing modern technologies and optimizing processes, the linen manufacturing company positioned itself for sustained success in the ever-evolving business landscape.